What Would Happen If You Didn't Flip One Piece Of Moulding?

(from Another Method For Adjusting A Logan Sander)

The reason you flip one piece of moulding is so each corner adjustment is considered separately. When you flip, you are actually adding Corner A to Corner A, which means the measured error will twice as much as the actual error, making it easier to measure.

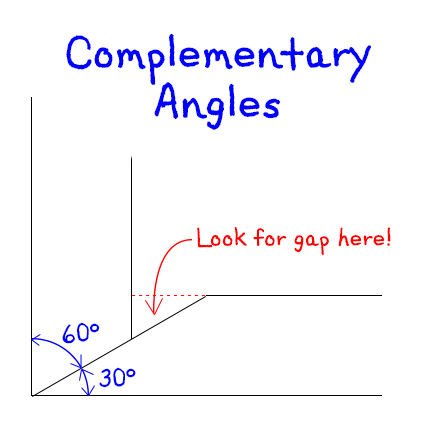

If you didn't flip one piece of moulding, when you put the two pieces together to get 90°, you would be adding one Corner A and one Corner B. If the result was a right angle, it wouldn't show that either of them was the desired 45°, it would only show that the two angles were complementary (meaning the two of them add up to 90°) - they could be 60° plus 30°. If they weren't both 45°, then the inner edges would not line up and you should see a gap along the inner edge of the corner with the smaller angle.

Angles were exaggerated for illustration purposes

Angles were exaggerated for illustration purposes

This illustration reminds me that for artistic reasons there are rare occasions that you might not want 45° corners on the ends of your moulding, but in those cases you would not be using the disc sander to "perfect" the joint, making that discussion beyond the scope of this article. Stay tuned for future articles on this topicexample.