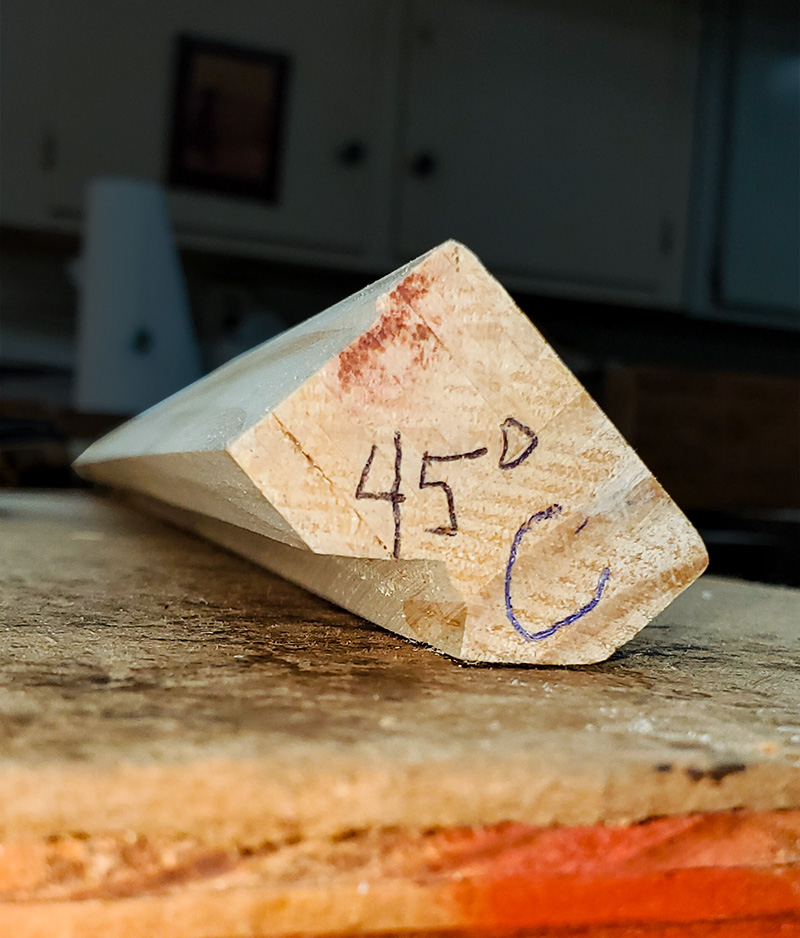

As I mentioned (and showed) in What’s New: Beveled-edge Gallery Wraps & Non-glare Acrylic, we’ve started putting bevels on the edges of our gallery-wrapped canvas images. The bad news is that you cannot buy beveled stretcher (or strainer) bars in any store; you have to make your own. The good news is that it’s not that hard. As a test, we tried mouldings with a 15° and then a 22½° bevel, but that wasn’t enough of a bevel to make it worthwhile. We’ve since used both 30° (as on “Burrowing Owls”details) and 45° bevels (as on “Cedar Keys Lighthouse”details), but are still perfecting the process. (Making the corner folds on 45° bevels is especially tough.) Here’s how we made our mouldings:

Building The Bars

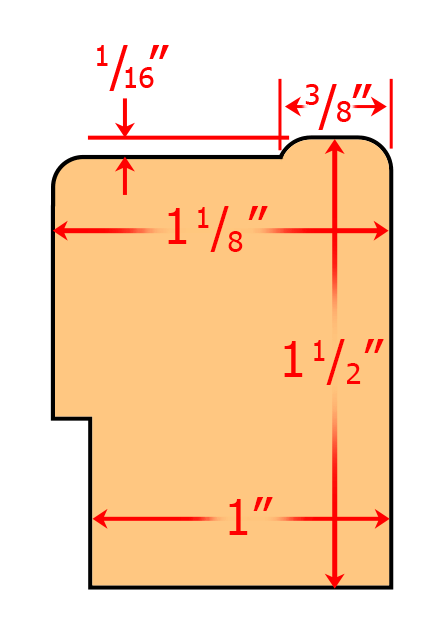

We didn’t start from scratch. The moulding we’ve been using all along for our 1½” gallery-wrapped canvas is the Strainer Stock Stretcher Unfinished 1⅛” (Item #6011) by Larson Juhlref, which you can get from Miami Decor Moulding when you are in the Miami-Dade area. |  |

The Plan

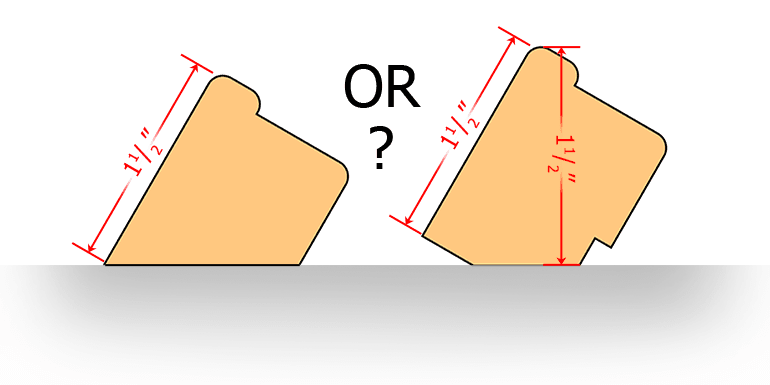

The plan was to just ripdefine the bottom of the moulding bar at the desired angle. We wanted the side face to remain 1½”. The first question was whether to remove everything below that or keep the total height of the moulding the same as the original.

We decided to keep the overall height the same because I was concerned about stretching the canvas over such a sharp corner. We later discovered that there were other important advantages to that option.

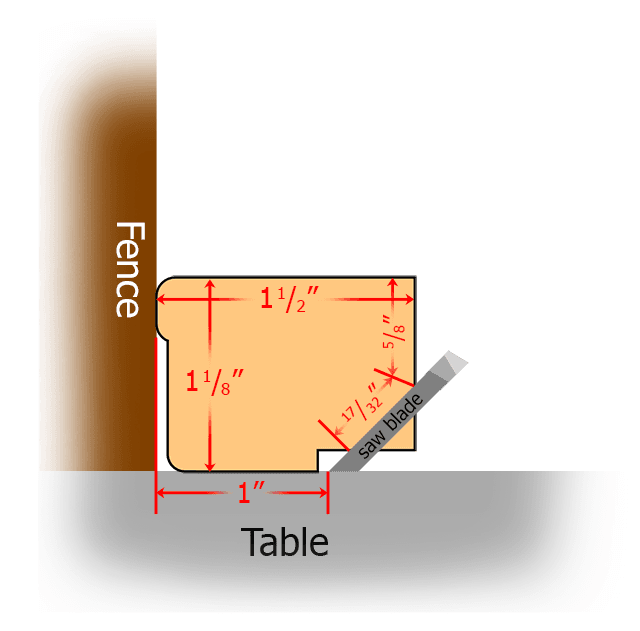

The First Cut

Above are the measurements for ripping an angled cut on the table saw. The fence should be 13/32” to make a 30° bevel and 1″ even for a 45° bevel.

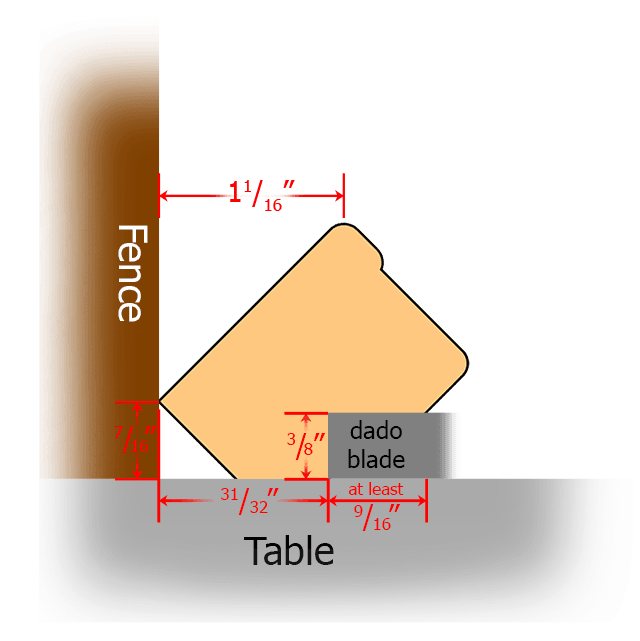

Strictly speaking, that’s all you need. But we’ve started using a dado bladedefined(video) to carve a perpendicular face on the inside edge of the new bottom to give our canvas pliers something to pry against when stretching the canvas.

Dado Cut

We make the cut ⅜” deep because that’s the depth of the spur (see note) on our canvas pliers.

And that’s all there is to it. Miter cuts will be the same; just remember to measure the moulding length at the peak, where the edge of your image’s front face will be, not along the outer edge. For 30° bevels, the overall (outside) length and width of your picture will be 1½” greater than with non-beveled moulding. For 45° bevels, that difference will be 2⅛”. Clamping your frame after gluing it together may be a bit more challenging, and you may need to do the V-nailing by hand.

What’s Next

I mentioned that there are other reasons to keep the total height of the moulding the same as before. One reason is that one might want to combine mouldings with different bevels into one frame; say to put a 30° bevel on the top and bottom and 45° bevels on the left and right, for example. If the bars were different heights, that would be extremely difficult. (It’s not a trivial matter even when they are the same height.) Although I hadn’t thought of beveled gallery wraps at the time, I inadvertently left a small hint for cutting their corner miters in Figure 14 of our blog article Using Multiple Moulding Widths In One Frame. Stay tuned.

[3/30/2022: see How To Join Mouldings With 30° & 45° Bevels.]

Leave a Reply